Brass

What is Brass?

Brass is a generic term for a range of mixtures (alloy) of copper and zinc. It has a lovely yellow colour that can range from quite pale to quite red depending on the proportions of copper to zinc. Other metals are often added to modify the characteristics of the brass.

Photos by Classical Numismatic Group, Inc. http://www.cngcoins.com

Brass was known to ancients and was extensively used by the Romans. It was often made into coins. They called the brass alloy they used orichalcum. Orichalcum had many recipes some even containing gold.

There is a long history of use throughout the world. Boat fittings and instruments were traditionally made of brass because of its corrosion resistance.

Muntz metal, a form of brass, was used in the days of wooden boats to line the wooden hulls of ships and other woodwork exposed to seawater and burrowing worms. It helped prevent fouling. This is what was used to line the hull of the Cutty Sark. It is an alloy of 60% copper, 40% zinc and a small amount of iron. It replaced copper which is more expensive.

The production of brass continued in the middle ages. Often the brass production centres were near sources of zinc. Calamine ore which is rich in zinc was used. Such areas as the Low Countries and Germany are examples of this.

Brass was often cast using the lost wax process and many great examples remain.

Brass has been produced in most parts of the world. It certainly occurred naturally where copper and zinc naturally came in contact.

African castings are world famous. Photo by Ukabia, Wikimedia commons.

Shaping Brass

Not only can brass be cast using the usual casting methods such as lost wax or sand casting but it can be drawn into wire, machined, rolled and formed. It has a long history of being hammered into shape and it can spun. This makes it an extremely versatile material. The addition of other metals and changing the proportions of zinc to copper modify the hardness, workability and machining characteristics.

What is the difference between brass and bronze?

The short answer is sometimes not very much!

Bronze is usually thought of as an alloy of copper with mainly Tin and Brass as an alloy of copper with manly zinc.

Bronze tends to be more brittle and harder than brass.

Since the terms Brass and Bronze are both general terms and quite imprecise and formulas for brass and bronze overlap there is no clear boundary.

Interesting article on Viking Bronze casting. The Vikings actually used alloy closer to brass than bronze. They often contained zinc and lead as well as copper and tin. Lead has the advantage of lowering the melting point of the bronze.

Uses of Brass

Musical Instruments

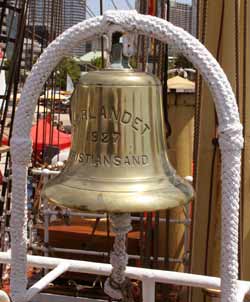

Being malleable and having suitable acoustic properties means brass is well suited in making musical instruments and bells. Brasses, as the group of wind instruments made from this metal are called, include trumpets, trombones, french horns and tubas. There are many variations worldwide. Cymbals and various percussion instruments are also made of brass.

The Canadian Brass Ensemble web page has a video.

Special use brass where sparks can be dangerous

Because brass does not create sparks the way iron does it often substitutes for iron in environments where fire is a danger. It is useful in explosive atmospheres as gas valves and fittings.

Uses in Corrosive environment such as fireboxes or in Marine Environments.

Many of the brasses are quite resistant to corrosion. This was used in the past for marine environments. The addition of aluminium is particularly successful in brasses used for seawater. If arsenic is also present the brass is suitable for boiler fireboxes, a highly corrosive environment.

Brass and Bronze use was extensive in ships and boats. Instruments, fittings such as cleats, blocks and fasteners were often made of brass, as were ships bells. There is a great deal of interest in the wooden boat community in brass and bronze fittings.

Tendercraft in Toronto has a good choice of boat brass and bronze fittings. Trinity Marine.co.uk has antique marine instruments.

Brass was a metal of choice for cannons on tall ships. Brass has the advantage of being less brittle than iron and could take the stress of the explosion without cracking as iron cannons sometimes did. I have an article on cannons from tall ships.

Brass has antibacterial and anti fouling qualities

Because mainly of its copper content, brass is an effective antibacterial surface. A great deal of experimenting is going on for use in hospitals. C difficile does not survive long on a brass (or copper) surface, nor does e-Coli, unlike stainless steel or plastic. Since many infections are transmitted by hands touching an infected surface, this is an encouraging fact.

Copper based paints have long been used in anti fouling paints and coatings for boat hulls. Before ships hulls began being coated in copper then brass many things were tried to keep the wood worms at bay. Capitain Cook covered his Endeavour with tar covered felt to protect her. Here is my page on tar based finishes.

Brass nets and meshes are also used in aquaculture to discourage growth on the enclosures.

Condensers and Heat Exchanger

Because of its corrosion resistance and high thermal conductivity brass is often used in heat exchangers and condensers. You can commonly see it used in air conditioning and heat recovery systems.

Industrial uses

Brasses can be formulated to be machinable cold, hard, tough, malleable, soft, hot workable. This gives industry a choice of materials that are easy to shape and corrosive resistant.

Pipes and valves are commonly made of brass and bronze.

High brass has high tensile strength and find many uses as fasteners, springs and rivets.

Decorative Objects

Brass is an attractive colour and has been used since antiquity for objects d'art and jewellery. It has also been used for architectural elements such as door handles, taps and light fixtures. It has also been used as gasket around windows and as kick plates. The house key is often brass!

Coins

Brass is used extensively for coins. The US Golden dollar is a Manganese brass while pound notes are made of Nickel brass. Euro coins are made from Nordic Gold, another brass alloy. Many other countries use brass or bronze coins.

Special use brass

Because brass tends to slide against itself smoothly having a low coefficient of friction, and is not subject to seizing as iron or aluminium is, it is often used where 2 metal pieces are in contact and it is important they not seize together. This is obvious for plumbing parts, zippers, or valves.

Brass and Bronze bushings are often seen in plain bearings (without ball or roller bearings) along with other metals. The softer bushing occasionally needs replacing but provides a good slippery surface.

Dezincification resistant Brass

These brasses resist the selective leaching of zinc from the brass alloy in particular when there is more than 15% of zinc in the mix. This occurs in brass taps where there is chlorine. It is a problem in sea water for such items as propellers.

Galvanic corrosion is a problem for brasses and causes the zink to be depleted. The result is pitting and weakening of the metal. This is seen in brass propeller. Specific formulations of brass fight this erosion. Admiralty brass has a small amount of Tin which inhibits dezincification. Arsenic is also sometimes added to brass for this purpose. Another alloy is called Dizincification resistant brass (DZR) and it is used among other things, to make drinking water fittings and pipes. A sacrificial zink piece is fitted near the brass underwater, and helps protect the brass from galvanic corrosion.

Recycling of Brass

Brass is recyclable and in fact is widely recycled. Heating brass has a tendency to vaporize the zinc and so this is factor in the recycling procedure. Copper gives no trouble at all and is the third most recycled metal after aluminium and iron.

Soldering and Braising of Brass

Brasses are readily soldered. Here is a link to an article on how to solder brass plumbing fittings. Bronze can be braised and this is sometimes done with an inert gas system. I once braised a sculpture to repair a part that had fallen off.

email me if you find mistakes, I'll fix them and we'll all benefit: Christine

Brass

Encyclopedia.com article on brass

Metal Supermarkets supply brass bars

Backyard Metal Casting.com has lots of DIY information on casting metals. Enjoy

Spartan Marine Hardware has marine bronze hardware.

Material Info

Plywood Grades which is worth reading if you're trying to sort out what to build your boat from.

Stitch and Glue Boatbuilding method

Rope Material Comparison How to decide what kind of ropes to use on your boat.

Small Print

I don't claim to be an expert in anything. Use safety equipment when working on your boat and wear a lifejacket when boating. Many coatings and paints are toxic or dangerous if used improperly. Many finishes have flammable solvents and components. As they dry, paints and varnishes often give off heat so any rag should be disposed of carefully and not left where the accumulation of heat can occur. Before using any product READ the label and take the warnings seriously.